Used to transport various hazardous and non-hazardous bulk materials, road tankers are vital in a range of industries.

Given the potential risks in road tanker transportation, regular inspection and testing of road tankers is a regulatory requirement, ensuring safety, compliance and operational efficiency.

For fleet managers, this is a key responsibility that requires meticulous attention to detail and proactive maintenance strategies.

Understanding Regulatory and Safety Standards for Road Tankers

The UK places stringent safety and compliance demands on road tankers to ensure the protection of those on the road, the environment and the materials being transported.

Regulatory bodies such as the Department for Transport (DfT), Vehicle Certification Agency (VCA) and the Health and Safety Executive (HSE) oversee compliance, with specific standards addressing vehicle maintenance, certifications and operational safety.

Key UK Regulations

- ADR Standards (European Agreement concerning the International Carriage of Dangerous Goods by Road): These set the framework for the safe transportation of hazardous materials and apply to both vehicles and their components.

- Periodic Testing Requirements: Road tankers must undergo regular testing to ensure their structural integrity and safety performance align with government-mandated standards.

- Pressure Vessel Safety Regulations: Tankers used for pressurised loads must comply with specific inspection and testing protocols to manage potential risks.

Non-adherence to these standards can result in severe penalties, legal liabilities and reputational damage. Fleet managers must prioritise regular inspections to remain compliant and safeguard their operations.

The Road Tanker Inspection Process

Inspection of road tankers covers an in-depth review of various key areas to identify issues and ensure vehicles are fit for purpose.

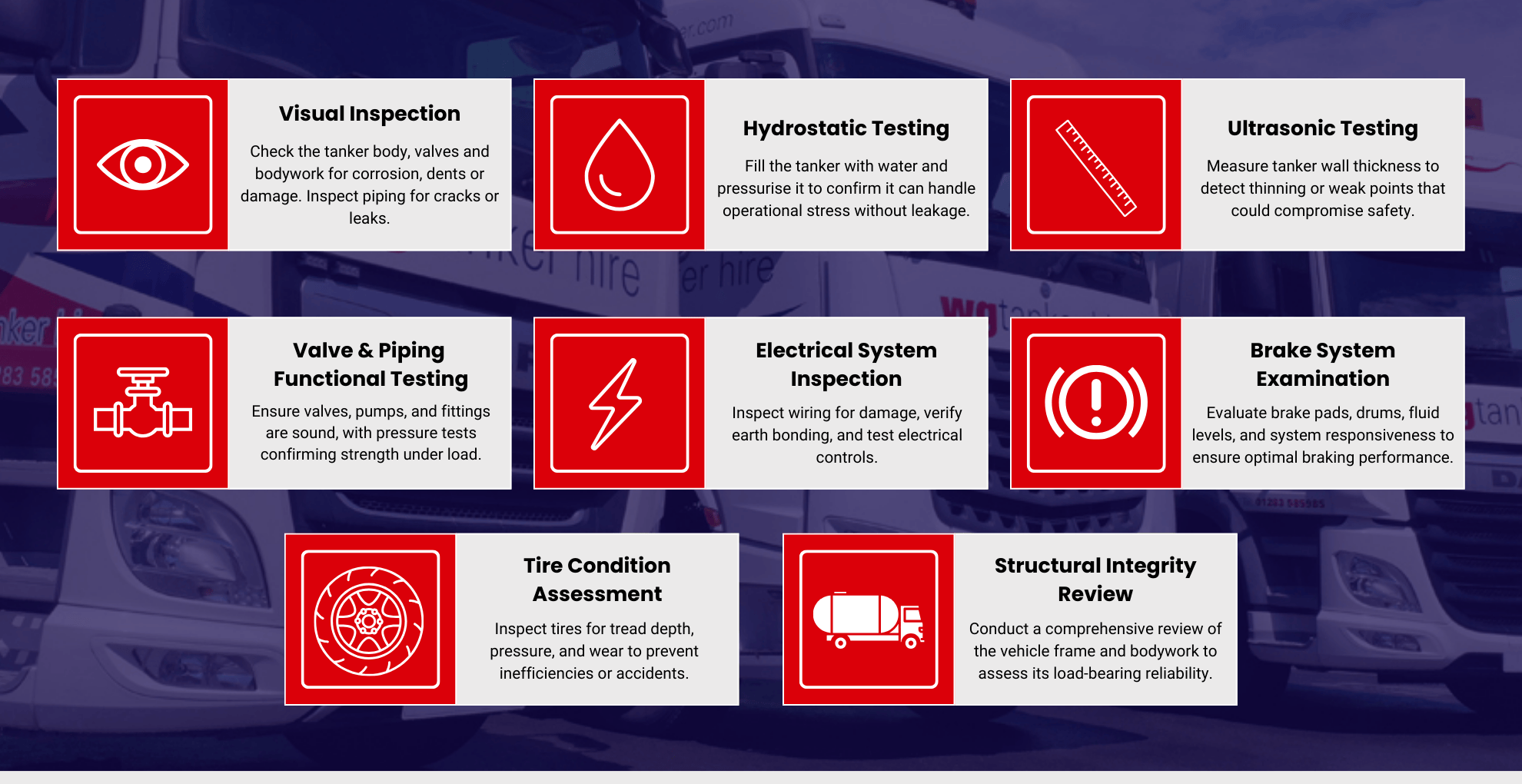

Visual Inspection

- Check for signs of corrosion, dents, or structural damage to the tanker body, valves and bodywork.

- Assess piping systems for visible cracks or leaks.

Tank Testing

- Hydrostatic Testing: Fill the tanker with water and pressurise it to confirm it can handle operational stress without leakage.

- Ultrasonic Testing: Measure tanker wall thickness to detect thinning or weak points that could compromise safety.

Valve and Piping Functional Testing

- Ensure valves, pumps and fittings are structurally and functionally sound. Pressure tests should confirm the strength of components under operational loads.

Electrical System Inspection

- Inspect wiring for damage, assess earth bonding for safety compliance and test electrical controls to verify functionality.

Brake System Examination

- Evaluate brake pads, drums, fluid levels, and system responsiveness to ensure optimal braking performance.

Tire Condition Assessment

- Inspect tires for tread depth, pressure, and signs of wear to prevent operational inefficiencies or accidents.

Structural Integrity Review

- Conduct a comprehensive review of the vehicle frame and bodywork to assess its load-bearing reliability.

Regular inspections, in alignment with these steps, ensure vehicles meet compliance requirements while minimising the risk of breakdowns.

Common Issues Found During Inspections

Inspections play a crucial role in maintaining the safety, efficiency and reliability of a fleet. However, fleet managers often encounter recurring issues that, if left unaddressed, can compromise safety, increase maintenance costs and disrupt operations. These issues require careful attention and timely resolution to prevent further complications.

Corroded Tank Walls

Corrosion is a common issue, especially for vehicles that transport harsh chemicals or operate in environments with high moisture or road salt exposure. Over time, it weakens the structural integrity of the tanker walls, increasing the risk of leaks or tank failure. Regular inspections, combined with proper protective coatings, can help mitigate this problem and extend the lifespan of the tanks.

Leaky Valves and Seals

Faulty seals or connections in valves and piping systems are another frequent concern. These leaks not only lead to material wastage but can also pose safety and environmental hazards, particularly if hazardous materials are involved. Proper maintenance, prompt replacement of components and pressure testing can reduce the likelihood of leaks.

Brake Wear

Brakes endure significant stress, especially in heavily loaded vehicles or those operating in stop-and-go traffic. Overused or improperly maintained brakes not only increase stopping distances but also heighten the risk of accidents. Regular brake inspections, adjustments and timely replacements are essential to ensure vehicle and driver safety.

Electrical Faults

Damaged wiring, blown fuses, or malfunctioning electrical components can lead to a variety of issues, from tanker equipment failure to compromised driver safety. Electrical faults may also affect critical systems like lighting, sensors or communication tools. Conducting thorough electrical inspections and addressing problems quickly can help prevent breakdowns and enhance overall performance.

Addressing these common problems promptly not only enhances safety but also reduces costly repairs, minimises downtime and ensures your fleet continues to operate smoothly and efficiently. Proactive maintenance and regular inspections are key to preventing these issues from escalating into larger, more expensive challenges.

WG Tanker Fleet Services

At WG Tanker, we understand the challenges fleet managers face and our leading tanker fleet services are here to help you overcome them. With years of industry expertise, we’ve built a reputation for delivering reliable, high-quality services designed to keep your fleet in top condition.

Our skilled specialists provide a comprehensive range of solutions tailored to your needs, including:

- Specialist Welding & Fabrications – Our team of skilled fabricator welders are fully equipped to meet the most up to date legislation and ISO regulations, carrying out all major pressure vessel damage body repairs, panel replacement and refurbishments.

- Comprehensive Bodywork Inspections – Ensuring the structural integrity and safety of your tankers.

- Advanced Pressure Testing – Identifying potential issues before they become costly problems.

- Tanker Repairs and Maintenance – From minor fixes to major overhauls, we’ve got you covered.

- Customised Preventative Maintenance Plans – Helping you stay on top of compliance and avoid unexpected breakdowns.

- Expert Guidance and Support – Partnering with you to ensure your fleet meets the highest industry standards.

Contact us today to learn how we can help you keep your fleet running smoothly and safely. It’s our business to keep your vehicles moving!